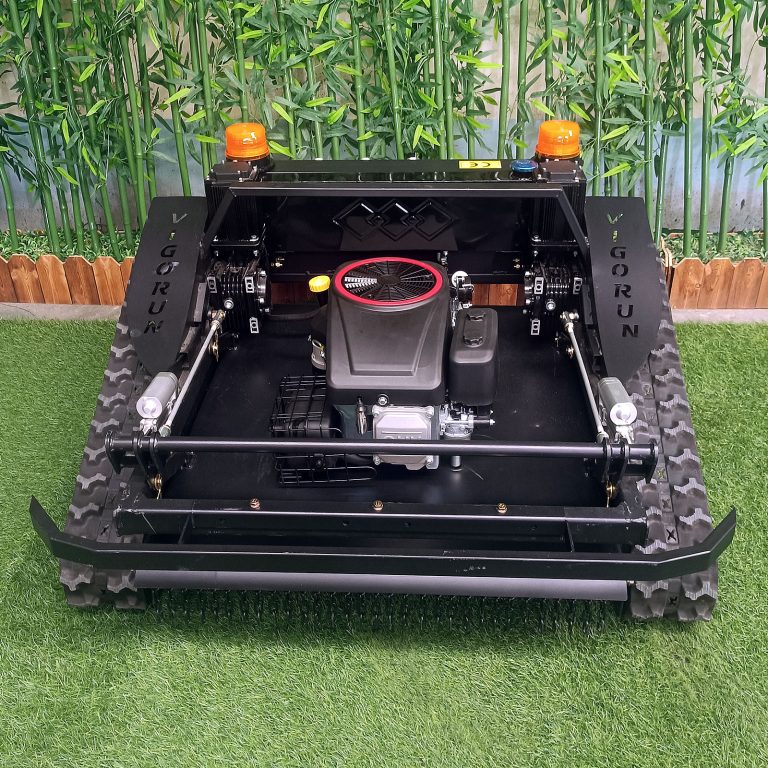

wireless radio control rotary mower for sale

Where Innovation Begins

Every powerful machine has a birthplace, and for Vigorun’s wireless radio control rotary mower, that place is a workshop filled with motion, sparks, and engineered precision. The video shared from our factory offers more than visuals—it reveals the ecosystem where ideas turn into machines. What looks like ordinary production space is actually a tightly coordinated flow designed to deliver consistent performance across every mower we build.

Vigorun Quality Starts in the Workshop—and Shows in the Field

Crafting the Heart of the Machine

Before the mower ever touches grass, its critical components take shape under careful craftsmanship. The footage highlights segments of our metal-processing stations: thick steel plates being shaped for durability, rotating shafts undergoing precision machining, and structural parts going through alignment tests. Each component serves a future purpose, whether it’s stabilizing the chassis on rough terrain or enabling smooth rotary cutting at high torque.

Top 3 track remote operated brush mower manufacturers in China

Vigorun Tech cordless track-mounted lawn cutter machine

wireless radio control rotary mower for sale

factory direct sales cordless track-mounted brush cutter

affordable low price tracked cordless bush mulcher for sale

Assembling Intelligence and Power

Once components pass inspection, they move to the assembly zone—where mechanical strength meets electronic control. This is where the remote-control system is calibrated and synchronized with the mower’s drive system. The process may seem simple, but the harmony between motors, sensors, and controllers determines how the machine behaves outdoors. The video subtly captures technicians verifying signal stability, reaction speed, and dual-motor coordination before the mower is cleared for outdoor testing.

A First Look at Real-World Movement

The most eye-catching part of the video is the mower maneuvering through the factory grounds. It pivots smoothly, accelerates cleanly, and responds instantly to operator commands. Even within a confined testing area, the mower shows its agility—traits that make it suitable for slopes, dense vegetation, and narrow or uneven landscapes. What viewers see as a simple demonstration is actually a stress-test simulation: a preview of the performance customers rely on in real conditions.

| Model | VTC550-90 | VTC550-90 With Snow Blade | VTW550-90 With Electric Start | VTC800-160 |

| Driving Method | Crawler | Crawler | Wheeled | Crawler |

| Engine / Power | Loncin 9Hp | Loncin 9Hp | Loncin 9Hp | Loncin 16Hp |

| Cutting Width | 550mm | 550mm | 550mm | 800mm |

| Adjustable Cutting Height | Yes, by remote | Yes, by remote | Yes, by hand | Yes, by remote |

| Self Charging | Yes | Yes | Yes | Yes |

| Package Size | 1010*980*780mm | 1280*980*780mm | 1050*900*590mm | 1360*1300*800mm |

| Gross Weight | 190kg | 205kg | 120kg | 298kg |

Built with Purpose, Delivered with Confidence

When the machine leaves the Vigorun factory, it carries more than assembled parts—it carries the result of consistent processes, specialized talent, and repeated testing. This is why our equipment is trusted across nearly 60 countries. The video captures only a small part of our daily operations, but it clearly reflects our commitment to delivering reliable, high-quality remote-controlled mowing solutions. For buyers, operators, and potential distributors, it represents a transparent look at the care and capability behind every Vigorun machine.